What the box reads on the outside...

Paperwork that is inside the box on top of the styrofoam. The quick guide on the left is bare bones and tells the DCC operator to go look up the product online and find the DCC guide. As of now, 20-20191-2 still doesn't have a detailed instruction manual and I never received a response from MTH on why. Instead, I had to go view the HO instruction manual and the DCC section there appears to mirror exactly the HO version as far as I can tell. You will need that to get the listing of the CVs, etc, but as a favor you reading this, I took a screenshot of the 29 functions and list it below:

So you never bought an MTH F or E ABA set huh...well this is what they look like brand new from the factory. Now try to wrap them back exactly like that each time you put them away...

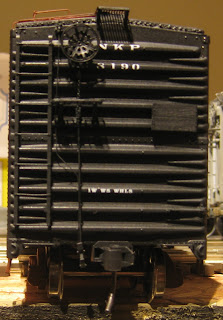

On my unfinished small switching layout, here is a look of the slave A unit with the kadees installed.

Side profile shot with that newly tooled blomberg truck. Pretty nice. I just wish they made it easy to change out the bearings used on their trucks and sold those as a separate detail pack as these trucks only have roller bearing on all 8 spots. Often many roads had mixed bearings on their units...

A close up of the pilot detail. They shrunk the hole for the kadee. Less huge gap for it. I like it. The screws for the kadees didn't come in the box like past 2R MTH diesels. I had to tap the holes for 2-56 screws. Obviously a freight pilot.

A closeup of the newly tooled blomberg trucks. Feel free to rivet count to your hearts content. Look good to me other than being stuck with the roller bearing sections.

An angle nose shot. I like how they added these service grabs, but these particular units never had them from what my references show. The font of the numberboard is also wrong.

The exhaust vent on both units came with the paint scraped off. Very odd...

So this is probably MTH's only 5-chime horn that comes close to an M5. The M5's were popular on many roads, so I am confused why they never made the casting. It must be replaced on both A units.

Here is the end of the slaved A unit. Rubber diaphragm/door along with rubber MU hoses. Not very realistic but I understand the desire for rubber airhoses. I will have to replace, along with putting the tether through the door.

The door on both A units open for the controls. Shown is the slave unit. Not much to select, but plenty of openings to get the tether through (or enlarge the openings...either way...

Here's what the main powered A unit has. Still room to get the tether through, but the current settings show that it is set for 2R DCC with the option to go to 3R (pickup rollers in box) or to DCS. I keep the smoke turned off, but these do supposedly smoke. I have no interest until after I do all the detail work. The sound POT does not work in DCC. Instead it is controlled by using the F6 key and can change it up 10 levels or so.

The lead A unit has this nasty creature for the tether along with the non-functional kadee and rubber air hoses.

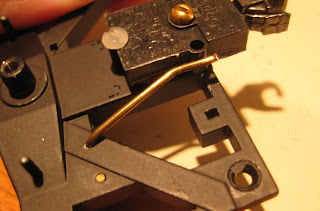

Here's what the truck blocks look like. Can easily screw in the 3R pickup roller. Look at the huge space between the 2R wheels and the frame. Supposedly easily fixable by John Sethian. I will await his detailed article at some point to proceed.

Added my Kadees with 2-56 screws. Tapping required I believe, but taking off the pilots was not.

Here's what the only speaker in this trio looks like. Comes with PS3 freight sounds and inspected by #1? Will look to expanding sound to the B and slave A unit.

Close-Up of non-function kadee between units.

A glimpse at the wiring mess of the tether...

Proof that these close couple as-is, but the tether is hideous. It will be completely hidden by the diaphragms once I get around to moving them. Wish MTH thought to move them first.

Now that the model is shown in detail, here is info on the prototypes MTH chose:

- Southern had 76 F7A units. Most were originally SOU with 9 from the CNO&TP and AGS.

- Southern had 72 F7B units. Most were originally SOU with 27 from both CNO&TP and AGS.

- These were all equipped with 567B engines.

- 4242 was built in 5/49 with Dynamic brakes installed in 23Oct53 at Spencer, NC shops.. Retired in 1969.

- 4228 was built in 6/49 with Dynamic brakes installed in 25May55 at Spencer, NC shops. Retired in 1973.

- 4400 was built in 5/49 with Dynamic brakes installed in 22Apr53 at Spencer, NC shops. Retired in 1969.

Using photos from both my physical and digital library...it would appear the following needs to happen to bring these closer to the prototype for my time frame(though all photos I have are only within my time frame, so I'm curious how MTH screwed up the service grabs...)

- Remove the service steps on both A units. They were not installed on these 2 particular units.

- Add the obviously missing MU and air hoses to the pilots.

- Add roof coils and spark arrestors to both 4242 and 4400.

- Replace the horns with brass Nathan M5 castings

- Add speed recorder and ATS shoes to appropriate trucks.

- Re-tether the ABA units through the diaphragm instead of through the truck.

- Redo MU hoses on rear of both A units and on both ends of B unit if feasible - Installed rubber ones may be required due to 36" radius curves

- Maybe try to add sound to the B and other A unit if feasible.

- Numberboard Font is off. Need to check Microscale decals to see if replacing is feasible.

- Potentially body mount kadees if feasible

- Potentially body mount side truck steps to frame if feasible

- Move the truck sideframes in if admittedly...John Sethian's way of doing it turns out to be easy.

- Get inside the nose lights/cab and paint the LEDs with orange translucent paint to make the bright white turn more warm white.

- Weather to 1968 conditions

Here is a video of my units to show a few of the functions easily achievable with my Digitrax DT402D. The video shows flickering of the lights, but it is entirely based on the camera's shutter speed seeing faster than our human eyes can and I can't easily fix it.

My final thought is that I wish MTH made some of these F7A units as dummy 2R units. Would be nice to run these elephant style as in the prototype.